Keep the factory in business More efficient

A small batch of multiple orders to produce artifacts

"Fast printing treasure" by more than 10 senior experts in the industry lasted 2 years of ingenuity, depth through the digital printing equipment, by more than 10 processing plants production verification.

From sales order to production printing, motion control, warehousing logistics, full link automation operation, realize the whole process of digital, fast delivery.

Empower a customized batch production capacity of the factory, aiming to improve the production efficiency of the factory, eliminate wrong orders, missing orders, reduce costs and increase efficiency.

One yard to the end

More、 Faster、Better、Less

2k+

Increase the capacity of equipment units

Production greatly increased

78%

Save money, labor and resources

Significant cost reduction

Digital empowerment

Digitalization of Management

Production order management

Planning and scheduling management

Production scheduling management

Process management

Production process traceability

Material and things management

Global multilingualism

Print device management

Large-screen data kanban board

Support PDA handheld

Sub-factory management

Quality management

Report work piece accounting

APP mobile workbench

Button-level permissions

Intelligent empowerment

Intelligent production

Scan code automatic transmission map

Scan code automatically report work

Scan code automatic delivery

Scan code to make electronic sheet

RIP automatic printing

Automated intelligent auditing

Automatic movement of the station

RFID automatic identification

Automatic order correlation

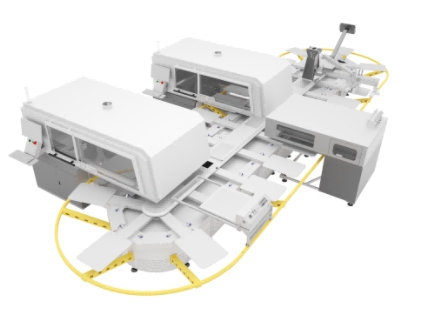

Wide range

Perfect fit for all DTG/DTF printing equipment on the market

Heat painting machine

adaptation

Station digital machine

adaptation

Elliptical digital machine

adaptation

Running table machine

adaptation

Leading the era of intelligent production in processing plants

Smarter, more precise, more flexible, more effective